ALTech is a world leading manufacturer of labelling machinery. We produce more than a thousand units per annum and

offer one of the widest ranges of label applicators, label print and apply and in-line labelling systems within the market.

With ever changing times we are constantly striving to innovate, improve, and advance our labelling machines.

We ensure that our machines are always at the top of the market in terms of performance, cost and reliability supplying

our customers with the best labelling system solution for their needs.

ALTech LA is a direct owned subsidiary of ALTech srl based near Cardiff in South Wales. We provide labelling systems

to all sectors of industry including, food, pharmaceutical, chemical and logistics to name but a few, with solutions tailored

to the particular segments needs.

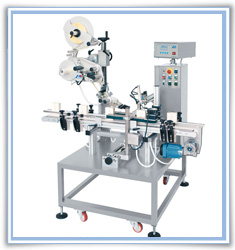

Low Cost Integrated Conveyor / Applicator Systems

ALbelt labelling systems are built to customers exact requirements in our South Wales workshops and incorporate one or more of our ALstep S (100mm, 30m/min) or M (200mm, 20m/min) workhorse apply only labelling heads, or ALstep T (110mm, 30m/min) batch print and apply labelling heads, to provide integrated low-cost conveyor based labelling solutions for a variety of low to medium volume applications.

Some more common ALbelt configurations include:

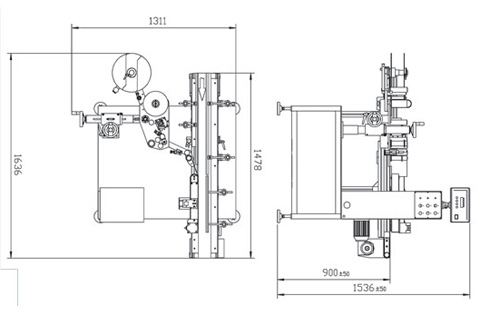

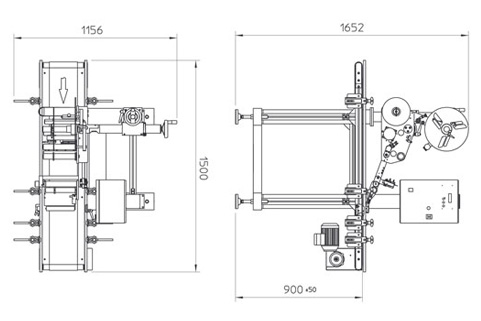

ALbelt C - Low Cost Wraparound Labelling System

We believe that our ALbelt C wraparound labelling system for jars, bottles and pots represents the best value conveyor based wraparound labelling system on the market today. The unit is ideal for both start up business or for customers looking for a progressive move to automated labelling acting as a stand alone machine with the potential to be used inline, with gapping and slated conveyor belt options available on request.

ALbelt C incorporates the same direct wraparound system as used on our high-performance ALline C wraparound labelling systems, providing excellent speed and accuracy for either full or partial wraparound labelling of flat sided cylindrical bottles, jars, tubs & pots ranging in diameter from 10mm to 180mm standard with larger diameter possibilities on demand.

The system can also be used for single side labelling of flat square faced products and can even handle cylindrical products with a small degree of taper making it extremely flexible especially when compared with desktop systems of a similar cost which would not allow such use.

As per all ALbelt systems, ALbelt C is also available with our Batch Print and Apply ALstep T labelling head to produce a highly cost effective print and apply wraparound labelling solution for applications requiring variable data overprinting - e.g. for overprinting product & ingredient information or batch code and best before data.

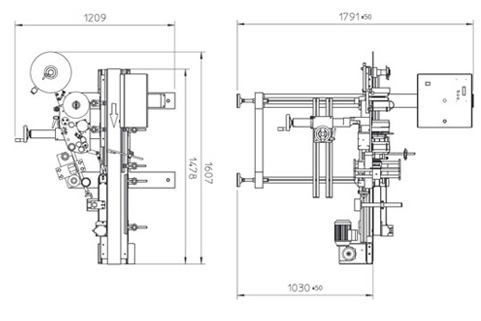

ALbelt E - Front & Back Labelling System

ALbelt E is configured with two horizontally opposed ALstep S (100mm) or M (200mm) labelling head s to provide a low cost integrated conveyor based labelling solution for front and back labelling of cartons and boxes, as well as pots and jerry cans and even, via the addition of our simplified belt and back plate orientation system, and top stabilisation belt, slightly elliptical cosmetic or chemical type containers.

ALbelt E can also be configured with the same direct wraparound labelling belt as found on ALbelt C to provide a highly versatile front, back and wraparound labelling solution - ALbelt EC.

ALbelt - Top, Bottom and combined Top & Bottom Labelling Systems

With hundreds, possibly thousands of configuration options, all based on known tried and tested modular systems, ALbelt can be configured to meet nearly any automatic labelling requirement from simple top labelling, to an integrated top and bottom labelling system with special split conveyor or high grip side belt system to expose the underside of the product for labelling.

A specialisation of ALTech is the manufacture of complete feed and handling solutions based around our ALbelt systems, with the option to upgrade our standard conveyor system to one with a built in vacuum system to securely hold light sheet or card product for labelling, working in combination with an automated feed system - such as a friction feeder or pick and place unit.

For uneven or variable height products such as pouches or punnets we also offer pneumatic & spring loaded peeler bar systems (as well as pneumatic tamp & blow solutions) which raise and lower between products accommodating any height differences, whilst adapting the label on the product using a special multi disk roller which follows the products uneven shape - liked by customers for their simplicity, speed and flexibility as compared to blow solutions.

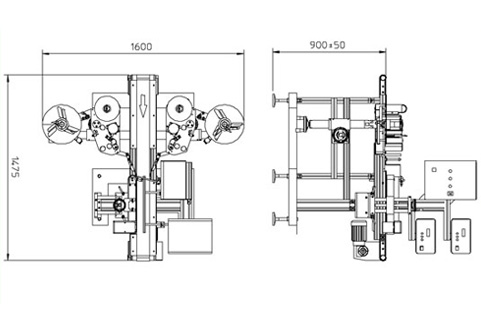

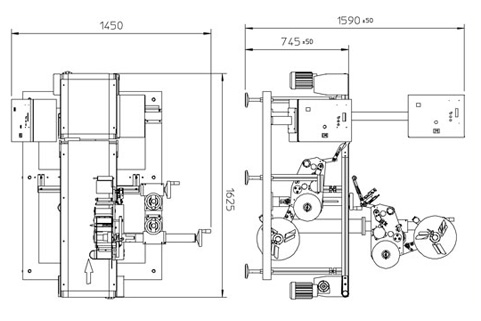

ALbelt XTRA - Solid Base ALbelt Labelling System

ALbelt XTRA is the latest addition to our labelling system family as part of constant strives for continual product improvement - bridging the gap between ALbelt and our top end ALline linear labelling systems.

The solid base provides improved system rigidity, with a top mounted rotatable control panel allowing programming from either side of the machine, and a more integrated aesthetically pleasing machine design, especially when fitted with a number of optional components such as infeed gapping wheel or synchronised side belts.

The system also provides the possibility of supply of a full stainless ALbelt labelling system should the customer application require such a solution.

Whatever your requirement ALTech UK are sure to be able to help. Please CONTACT US for details

| Albelt C |

| Albelt E |

| Albelt Top |

| Albelt Top & Bottom |

| Albelt XTRA |