ALTech is a world leading manufacturer of labelling machinery. We produce more than a thousand units per annum and

offer one of the widest ranges of label applicators, label print and apply and in-line labelling systems within the market.

With ever changing times we are constantly striving to innovate, improve, and advance our labelling machines.

We ensure that our machines are always at the top of the market in terms of performance, cost and reliability supplying

our customers with the best labelling system solution for their needs.

ALTech LA is a direct owned subsidiary of ALTech srl based near Cardiff in South Wales. We provide labelling systems

to all sectors of industry including, food, pharmaceutical, chemical and logistics to name but a few, with solutions tailored

to the particular segments needs.

High Performance In-Line Wraparound Labelling

ALline C is a high performance, fully featured in-line wraparound labelling machine for flat sided or slightly tapered cylindrical products . These include plastic, glass or metal jars, vials and bottles containing foodstuff, chemicals, cosmetic & pharmaceutical products.

As with all ALTech labelling machines, ALline C is designed in a modular format and can be configured with an infinitely variable choice of gapping systems, labelling heads and / or coding solutions . These are chosen according to the products to be labelled and the performance requirements of the application.

Typical label application speeds vary from between 80-200 products per minute dependent on the label and product dimensions ; a maximum of 300 products per minute can be achieved for bespoke solutions.

Standard product spacing solutions for the ALline C include:

- Gapping wheel

- Side belt spacer

- Dual belt spacer

- Scroll drive

- Pneumatic gate

ALline C can be configured with either our workhorse ALstep or performance ALritma / ALritma X labelling head series mounted on highly precise twin tube adjustment systems.

Further options exist to add micrometric inclination (i.e. to match a products taper) and/or visual axis counters, providing setup and changeover procedures that are particularly simple, intuitive and repeatable.

ALritma based solutions include a powerful touch screen control system allowing setting and storage of all the labelling parameters related to the particular label and product combination..

These can then be stored as a format with a definable name - e.g. “1Ltr” meaning each job only requires setting up once, from which point settings can just be recalled electronically, massively speeding product changeovers.

A comprehensive array of devices are available for label wraparound - with standard direct wrap machines capable of either full or partial wraparound labelling on flat sided or slightly tapered containers.

Further wraparound options include the potential to label in-phase (e.g. with a pre-existing print registration) via a special three roller system or on the front and back of the product via our unique vacuum wraparound system.

This innovative system can also be configured to provide a non-stop labelling solution (via two labelling heads feeding the same vacuum belt) or for high speed in-register label application with an in-line applied lid or neck label.

The core wraparound application solutions for ALline C can be visualised here:

- Direct wraparound

- In-phace wraparound

- Vaccum wraparound

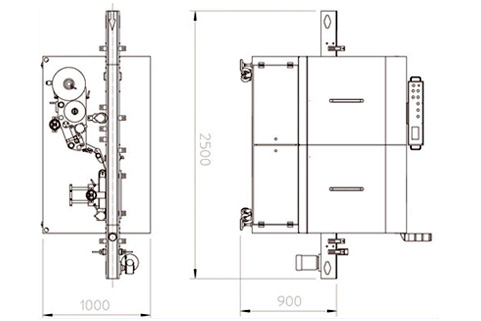

Typified in its design by a compact solid base structure, ALline labelling systems include as standard a high degree of water ingress protection, stainless steel top plate & module components and an upper mounted control panel, providing a user friendly operator interface and of course inherent liquids protection.

For particularly harsh environments ALline C can also be specified with an enclosure and/or full stainless 304 or 316 construction - i.e. for wet or corrosive environments.

The robust base can be mounted with several kinds of slat or belt conveyors, of differing widths and lengths to meet customer requirements whilst ensuring system rigidity and thus, consistent alignment of all the labelling elements and consequently accurate labelling.

Machines can also be mounted with a wide range of coding solutions such as hotfoil, intermittent thermal transfer (e.g. Markem or ICE coders) or full inline thermal print engines such as SATO or Zebra for complete in-line label printing with text and barcodes.

They can also be configured with label application checking devices and product rejection systems - or for stand alone solutions, with rotary in feed and out feed tables for automatic feed and take off.

| Power supply | 400V 50 Hz three-phase |

| Power consumption | 1 Kw |

| Performances | Up to 500 pos/min adjustable |