ALTech is a world leading manufacturer of labelling machinery. We produce more than a thousand units per annum and

offer one of the widest ranges of label applicators, label print and apply and in-line labelling systems within the market.

With ever changing times we are constantly striving to innovate, improve, and advance our labelling machines.

We ensure that our machines are always at the top of the market in terms of performance, cost and reliability supplying

our customers with the best labelling system solution for their needs.

ALTech LA is a direct owned subsidiary of ALTech srl based near Cardiff in South Wales. We provide labelling systems

to all sectors of industry including, food, pharmaceutical, chemical and logistics to name but a few, with solutions tailored

to the particular segments needs.

Pharmaceutical Products Labellers

The ALpharma range of self-adhesive labelling systems has been specially devised by ALTech for the labelling of pharmaceutical products.

Based on the wide experience we have gained in designing innovative labelling systems over the last 20 years, which are extremely successfully proven in all market sectors, we have specifically developed the ALpharma labelling system range, which include a range of highly advanced features and are built to fully comply with the strict rules and regulations of the pharmaceutical industry.

The ALpharma labelling machine range have all been designed according to the comprehensive standards set out by the “Good Engineering Practices” (GEP) standards, with special attention to a range of specific needs, which include:

- Easy cleaning of the machine thanks to its smooth surfaces, with a minimal amount of catch points and a high position of the electrical parts and/or their protection against liquid spills.

- Ergonomic mechanical parts, easy format change, repeatable settings.

- Extremely high quality materials, especially stainless steel (AISI 304 or 316).

- The integration of label printing devices for the print of essential data (batch codes, sell-by dates), by means of hot foil or thermal transfer printing units.

- The integration of sensors to check for correct application, and or overprinting performed and legible.

- The possibility of integration of an in-built control system equipped with a Siemens S7-300 PLC and a touch screen interface which manages all functions of the machine and its checking devices.

- The possibility of certifying the machine as per GAMP 4 (IQ/OQ/PQ) validation process, with the provision of the related documents and the performance of tests (FAT, SAT) according to these procedures.

There are currently three basic ALpharma models:

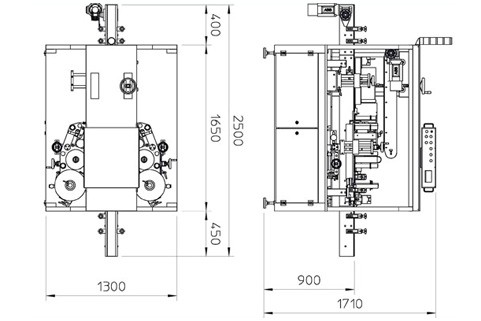

ALpharma A: The ALpharma A is designed for labelling vials and small bottles. The labelling is performed from tray to tray, “in-the-star-wheel”. Up to 150 products/min.

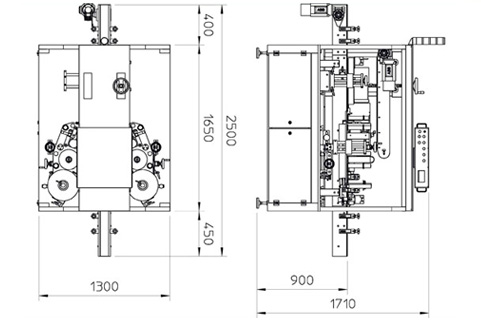

ALpharma B: The ALpharma B is designed for labelling shaped cases, with both bar code labels (tags, vignettes) and tamper evident angle labels folded along the flaps (up to 200 products/min).

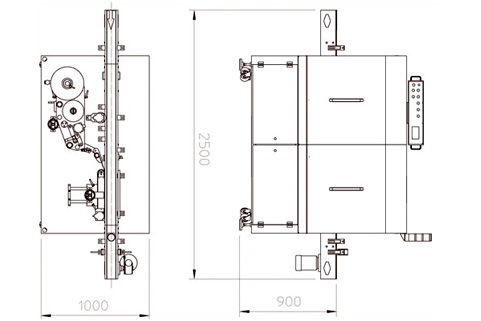

ALpharma C: The ALpharma C is designed for in-line wrap-around labelling of small, cylindrical bottles. Up to 250 products/min.

Please CONTACT US for further details

| Power supply | 400V 50 Hz three-phase |

| Power consumption | 1 Kw |

| Performances | 150 pcs/min |

| Power supply | 400V 50 Hz three-phase |

| Power consumption | 1 Kw |

| Performances | 200 pcs/min |

| Power supply | 400V 50 Hz three-phase |

| Power consumption | 1 Kw |

| Performances | 250 pcs/min |