ALTech is a world leading manufacturer of labelling machinery. We produce more than a thousand units per annum and

offer one of the widest ranges of label applicators, label print and apply and in-line labelling systems within the market.

With ever changing times we are constantly striving to innovate, improve, and advance our labelling machines.

We ensure that our machines are always at the top of the market in terms of performance, cost and reliability supplying

our customers with the best labelling system solution for their needs.

ALTech LA is a direct owned subsidiary of ALTech srl based near Cardiff in South Wales. We provide labelling systems

to all sectors of industry including, food, pharmaceutical, chemical and logistics to name but a few, with solutions tailored

to the particular segments needs.

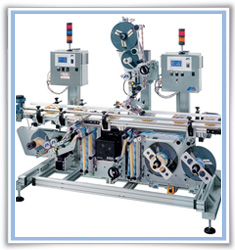

High Performance, High Precision Label Applicator

ALritma is a high performance self-adhesive label applicator for labelling applications where production speed and placement accuracy are primary needs. It offers a label application speed of up to 40m/min (or up to 500 products per min dependent on label size and pitch) and a placement accuracy of better than +/- 1mm.

ALritma’s IP55 rated innovative mechanical structure can be orientated in any rotation and is ultra robust, suitable for business critical applications in even the harshest industrial environments.

It is available in three versions, S, M and L, for label leading edge widths up to 100, 200 and 300 mm respectively and is controlled by an separate mounted intuitive multi language touch screen control system with a host of advanced functions for even the most demanding labelling applications.

Designed in a modular manor, ALritma includes a comprehensive selection of application options to solve even the most complex label application requirements.

A few of our standard label application solutions include:

- Fixed peeler with adapting sponge roller

- Spring loaded peeler with multi-disk roller (for uneven products)

- Pneumatically driven peeler with sponge roller or multi-disk roller (for variable height or very uneven products)

- L - shaped pendulous peeler (for corner labelling)

- Air blow - with / without piston (for non-contact labelling)

On the very rare occasion where a standard application solution does not exist, we have the experience and expertise to design custom label application solutions or machine configurations.

ALritma’s powerful microprocessor controller provides the user with all the most common adjustment functions in one simple main screen. Once set these functions can then be saved for up to 40 product/label combinations, considerably simplifying and speeding product changeovers.

Further control functions include:

- Pre-dispensing adjustment (to align variable label length to the end of the peeler bar)

- Adjustment of label dispensing speed in 0.1meter increments

- Labelling delay adjustment in 0.1mm increments (999mm max delay) with products shift register

- Storing of up to 40 different label/product formats with application definable name (e.g. 1 Ltr)

- Labels applied counter

- Automatic recovery of missing labels on the reel

- Progressive and regressive “products labelled” counter

- Automatic removal of double product detection (via sensor adjustable sensor inhibit function)

- Label “Flag” function - e.g. for C- wrap labelling

- Real time labelling delay algorithm for perfect label placement, even with speed variation (with optional encoder)

- End-of-roll alarm and web break alarm

- ◦Output connection to other systems (e.g. to stop the packaging line in case of error)

Additionally, ALritma can be equipped with an array of ancillary devices to solve specific labelling problems, such as:

- Hot foil printing unit* (for fixed batch or date coding)

- Checking device for near end of reel with alarm beacon*

- Automatic speed matching via encoder with delay algorithm to maintain label placement position.

- Non-stop controller device for sequentially-placed applicators for zero downtime

- Checking device for “label applied”

- Label sensor for transparent material*

- In-line thermal print engine* (ALritma T)

- Integrated conveyor systems (ALbelt)

*options can be retrofitted with no major mechanical modifications after the machine has been installed.

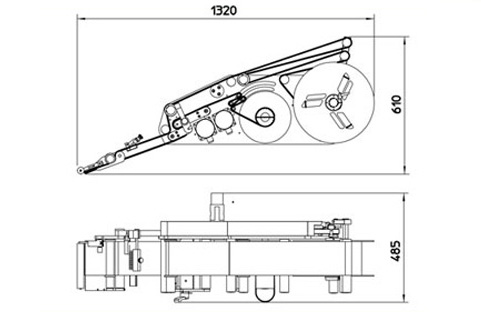

| Label width (mm) | Max: 100(S); 200(M) 300(L) | Max speed | 40 mt/min (60&80m/min opt) |

| Control | Display touch screen | Memory capacity | 40 formats |

Machine body protection |

IP55 | Unwind unit Ø | 300 (opt.350/ 400) mm |

| Standard alarms | end of roll - web break - drag open | Missing labels recovery | current |

| Near end of roll check | optional | Pneumatics applicators | optional |

| Encoder | optional | Transparent label sensor | optional |

| Coder / TT printer | optional | AC Power | 240 V - 50 Hz - 400 W |